MATERIALS

We offer plastic sheet, rod, and tube along with our fabrication. By keeping everything under one roof we maximize efficiency and quality control! We stock hundreds of variations of materials for your convenience and are constantly expanding our inventory to meet our customers needs! Below are a few of the many materials we offer! Please give us a call at 717-593-9200 and we can help you further!

|

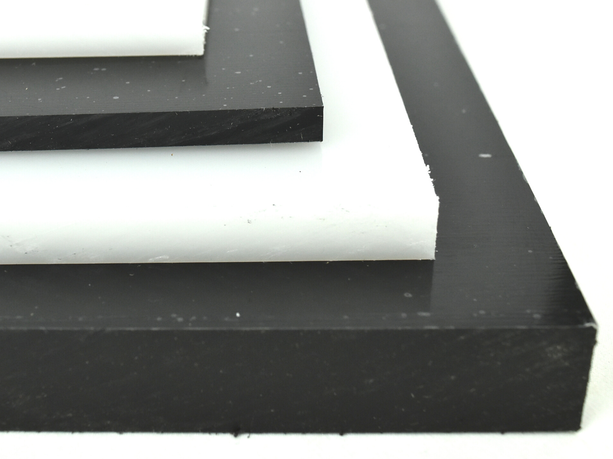

ABS

ABS is a low cost engineering plastic that is easy to machine and fabricate. ABS is commonly used for structural applications when impact resistance, strength, and stiffness are required. It is widely used for fabricating prototypes since it has excellent dimensional stability and is easy to paint and glue. Natural (beige) ABS and black ABS are FDA compliant for use in food processing applications.

|

|

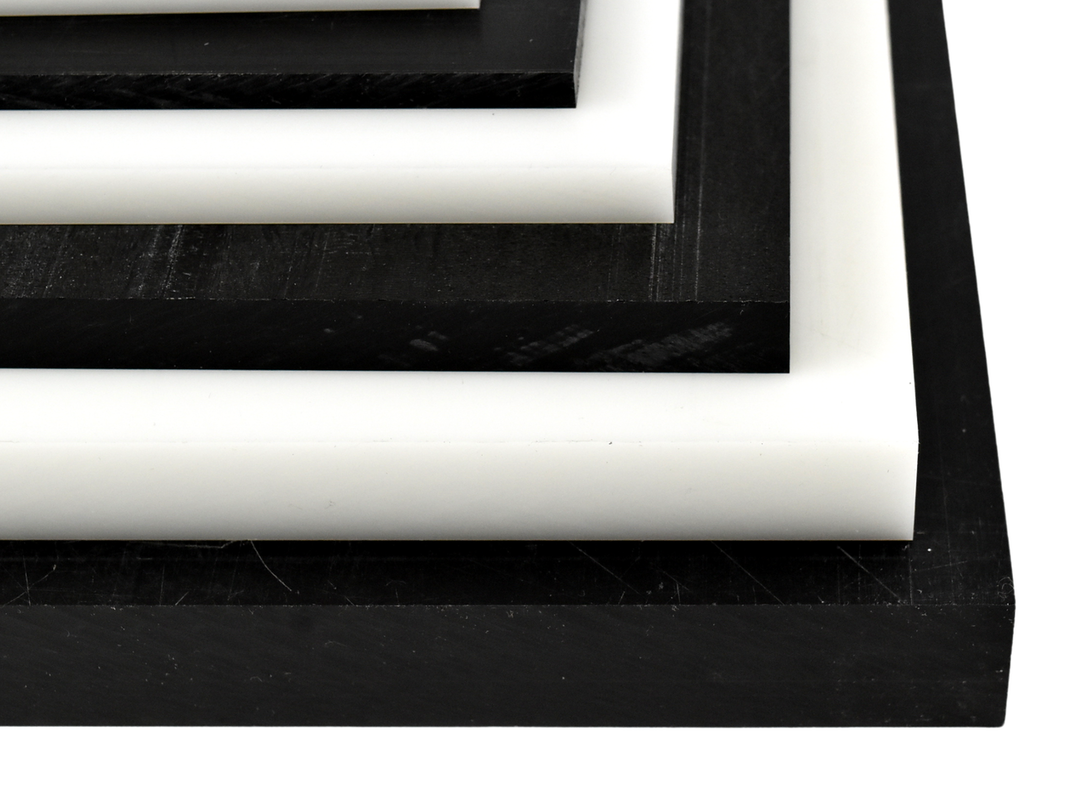

ACETAL

Acetal has excellent properties that bridge the gaps between metal and plastic. It is known for low moisture absorption, high tensile strength, creep resistance, and durability. With outstanding chemical resistance solvents and other natural chemicals, Delrin sheets are ideal for industrial applications. There are two main types: copolymer and homopolymer.

|

|

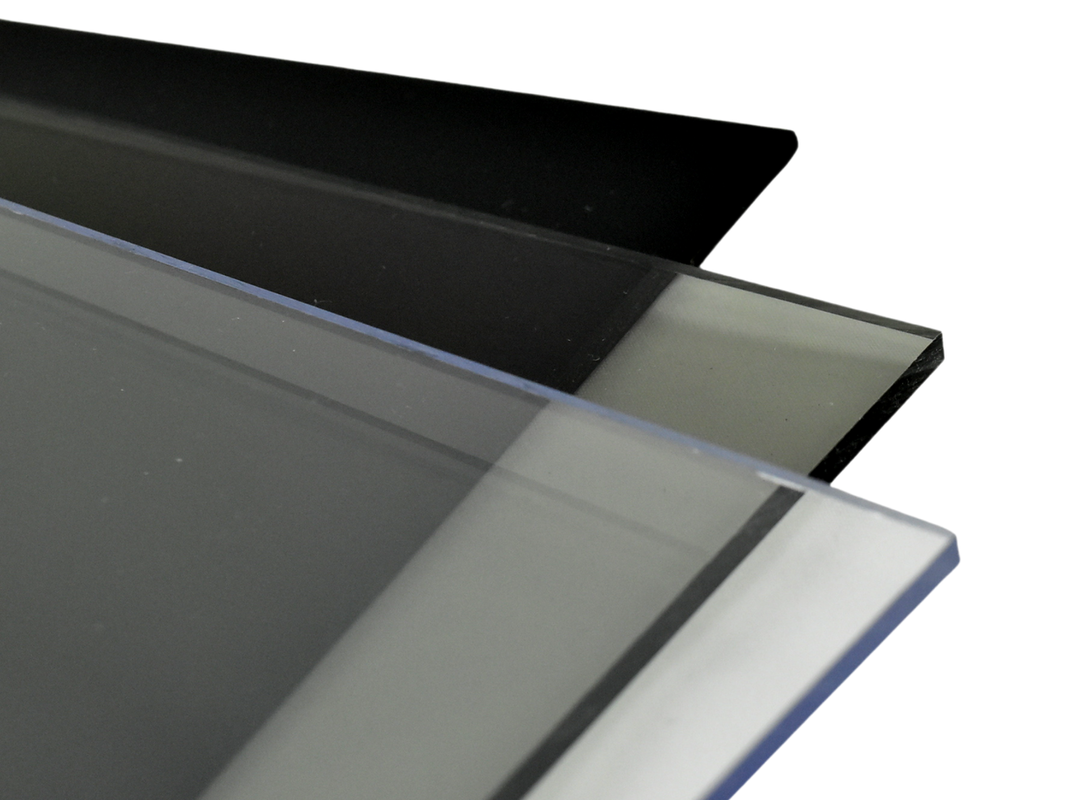

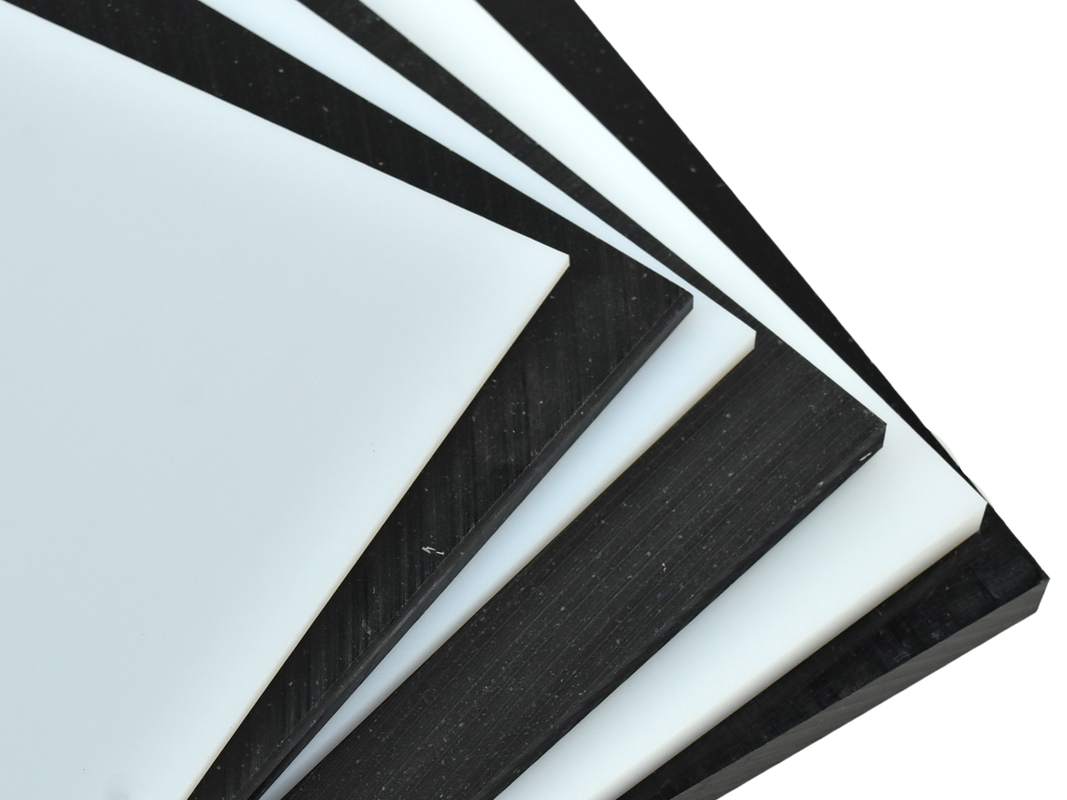

ACRYLIC

Acrylic is a clear thermoplastic with about 92% transparency, making it useful in many optical applications. Acrylic has better impact resistance and transparency than glass. It can be easily machined, glued, and painted. Acrylic can also be thermoformed. Acrylics are typically made by one of three methods: extrusion, continuously manufactured, and casting. The main difference is that extrusion has a lower molecular weight and casting has the highest molecular weight. Extrusion and cast acrylic frequently overlap at 1/4 to 3/8 thicknesses with cast being the thicker materials.

|

|

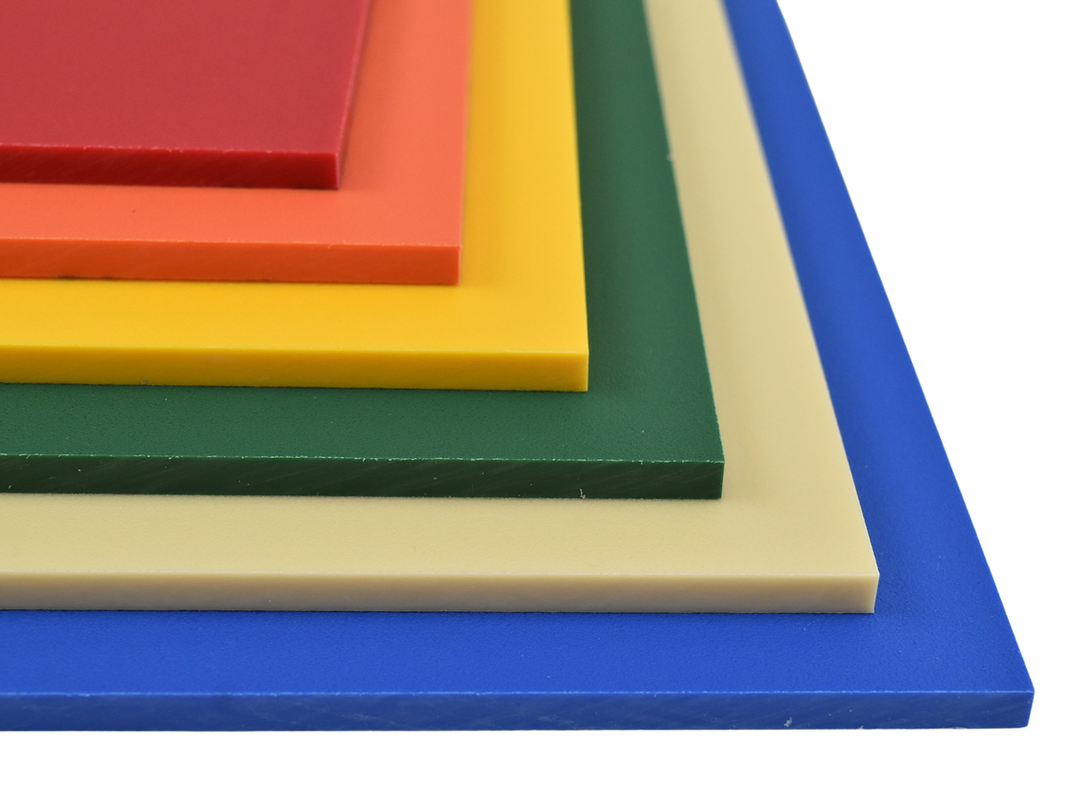

HDPE

HDPE (high-density polyethylene) is one of the most widely used plastics. Machinability, chemical resistance, impact resistance, water resistance, strength, and low coefficient of friction are just a few of the properties that make HDPE a popular choice. The many colors, textures, and thicknesses give you a lot of room for customization. HDPE is used across many industries such as marine, medical, food processing, nuclear, agriculture, sign, and manufacturing.

|

|

HY-PACT

There are cases where the abrasion and impact-resistance of UHMW is not necessary. So the King team created King Hy-Pact® (very high molecular weight polyethylene), a unique product designed to be a perfect complement to UHMW and to bridge the wide performance gap between HDPE and UHMW. When used properly, King Hy-Pact allows distributors and manufacturers to reduce costs while suffering no performance loss. Good design practices dictate that new applications should always be tested before full-scale operations begin.

|

|

LDPE

Low-density polyethylene extruded sheets are very pliable with a smooth soft translucent appearance. LDPE stock sheet is ideal for applications such as stencils, orthopedics, packaging, sound deadening, and the automotive industries. Other applications may include trays, general-purpose containers, food storage, laboratory containers, and corrosion-resistant work surfaces. LDPE sheets are also used for applications where corrosion resistance is a factor but stiffness, high temperatures and structural strength are not.

|

|

NYLON

Nylon is great for extreme wear applications. The following properties is the reason: high wear resistance, high impact resistance, high abrasion resistance, high temperature resistance, excellent chemical resistance, and low coefficient of friction. Applications are bearings, bushings, sprockets, rollers, pulleys, etc. Oil-filled nylon offers lower coefficient of friction and glass-filled nylon offers greater thermal stability and higher wear resistance.

|

|

PEEK

PEEK is an engineering plastic with outstanding resistance to harsh chemicals. Unfilled PEEK is naturally abrasion resistant.

|

|

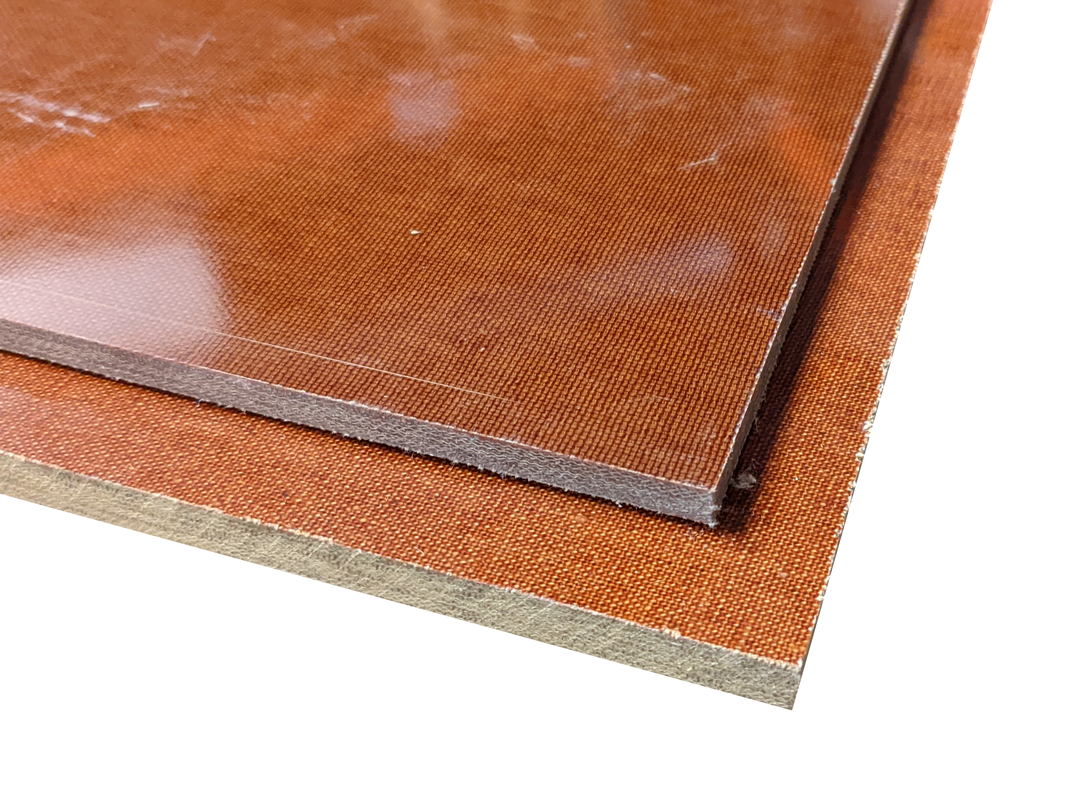

PHENOLIC

Phenolics are the result of polymerization between layers of paper, canvas, linen, or glass cloth impregnated with synthetic thermosetting resins. Phenolics are strong and stiff and have excellent creep resistance and outstanding dimensional stability

|

|

POLYCARBONATE

Commonly known as Lexan or Tuffak. Polycarbonate is a high-impact resistant alternative to acrylic. It is used in industrial applications such as windows, shields, and enclosures. Polycarbonate is 250 times stronger than glass. It can be cut, drilled, and formed without cracking. Since it has a low scratch resistance a hard coating is applied to the Polycarbonate AR. It is available in limited colors, abrasion resistant, and UV resistance.

|

|

POLYPROPYLENE

Polypropylene products offer excellent chemical resistance. They resist organic solvents, de-greasing agents and electrolytic products. They also have high stain resistance with low moisture absorption. Polypropylene has exceptional impact resistance at room temperature and is stiffer than HDPE or LDPE. It is FDA approved for food service applications.

|

|

PVC

PVC is a thermoplastic material with excellent chemical resistance and dielectric properties, good tensile, flexural and mechanical strength, low moisture absorption, exceptional dimensional stability and good flammability characteristics. There are hundreds of formulations available for desired physical properties targeted to a specific application. PVC is available in a wide range of colors as well as transparent variations.

|

|

PVC/ACRYLIC ALLOY

PVC/ACRYLIC ALLOY is a thermoplastic that has great formability, rigidity, breakage resistance, chemical resistance and fire retardancy. PVC/ACRYLIC ALLOY is available in a wide range of standard and custom colors, textures, and sheet sizes.

|

|

PVDF

PVDF is a very pure UB stable thermoplastic fluoropolymer that has great chemical, abrasion, and flame resistance properties. PVDF is often used for chemical tank liners and semiconductor equipment components.

|

|

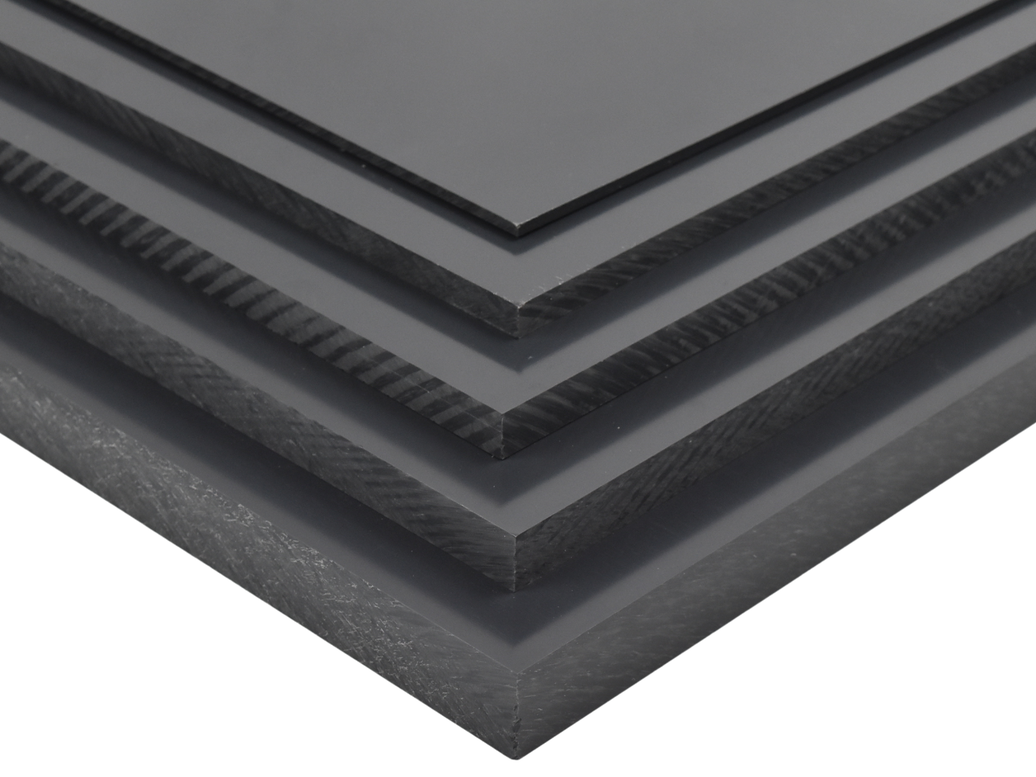

UHMW

UHMW is used for long-term abrasive and wear applications. High-impact resistance, low coefficient of friction, and chemical resistance are a few of the properties that make this a great choice for bushings, wear plates, chain guides, and bed liners. Glass-filled UHMW improves the hardness and thermal expansion. Oil-filled UHMW enhances the low coefficient of friction even more. Anti-static UHMW reduces static discharges in potentially volatile conditions such as grain elevators.

|